This is our sixth sustainability report, prepared according to the GRI Standards: Core Option. In this report, we present our performance, provide insights into the outcome and achievement during FY 2019-20 in generating and distributing both financial and non-financial value. Further, the report also delineates our journey in addressing various environmental, social and governance risks across business units. The information included in this report has been structured under six capitals in line with the International Integrated Reporting Committee (IIRC) Framework. It follows the principles of stakeholder inclusiveness, materiality, sustainability context and completeness. We publish our sustainability report annually. Through sustainability reporting, we strive to highlight the steps taken towards reducing our environmental footprint by building upon the three pillars of Aditya Birla Group’s Sustainability Framework: Responsible Stewardship, Stakeholder Engagement and Future- Proofing.

We have aligned the report to the 17 SDGs released at the UN Sustainable Development Summit in 2015 which embraces a universal approach to the sustainable development agenda.

This is a combined sustainability performance and progress report of ABG Textiles - Domestic Textiles, Acrylic Fibre and Overseas Spinning located in India, Indonesia and Thailand. This report presents the performance of Jaya Shree Textiles and Vikram Woollens (grouped as Domestic Textile Business), PT Elegant Textiles, PT Sunrise Bumi Textiles, Indo Liberty Textiles and Indo Thai Synthetics (grouped as Overseas Spinning Business) and Thai Acrylic Fibre (grouped as Acrylic Fibre Business) but exclude the Indo Phil Textile Mills (IPT), Philippines, Grasim Premium Fabric Private Limited (GPFPL), Kolhapur. Spinnerei Lampertsmuhle GmbH (SPL), a German Technical Textiles spinner and PyroTex Industries GmbH, Germany. GPFPL, Pyrotex and SPL have been acquired/merged very recently and are preferred to be out side for this combined reporting. The purpose of this report is to detail the sustainability initiatives implemented, progress made and plans and milestones in the business operations of these units.

We want to improve sustainability practices continuously to ensure that we meet the highest performance and disclosure standards and expectations of all our stakeholders, as well as increase the visibility of our efforts in creating sustainable value for our stakeholders. We, therefore, welcome any views on the sustainability performance and plans reported herein, content and design of the report. Queries related to this report may be written to jagadish.barik@adityabirla.com

ADITYA BIRLA GROUP

A US$ 48.3 billion corporation, the Aditya Birla Group (ABG) is in the League of Fortune 500, anchored by an extraordinary force of over 120,000 employees, belonging to 42 nationalities. Over 50 per cent of its revenue flows from its overseas operations spanning 36 countries.

Aditya Birla textiles is a part of the Aditya Birla Group (ABG). Aditya Birla Textiles businesses are a voluntary coalition of its textile units which comprises of Domestic Textiles, Acrylic Fibre and Overseas Spinning. The manufacturing facilities are present in India, Indonesia, Germany, Spain and Thailand with market presence across the globe.

The Domestic Textile business comprises of a flagship business of Aditya Birla Group, Jaya Shree textiles (JST) and Vikram Woolens (VW). JST and VW are the units of Grasim Industries Limited. Grasim Industries Limited is a company incorporated and domiciled in India and ranks amongst the top publicly listed companies. Today, it has evolved into a leading diversified player with a leadership presence across many sectors. It is a flagship company of the Aditya Birla Group. Grasim is engaged primarily in Viscose (Pulp, Fibre and Yarn), Chemicals (Caustic Soda, Epoxy and allied Chemicals), Fertilisers, Insulators, Textiles and other businesses. At Grasim, there is an endeavour to create sustainable value for 24,123+ employees, 2,33,934 shareholders, society and customers. It has a consolidated net revenue of over ₹77,625 Crore and an EBITDA of over ₹13,846 Crore in FY 2020.

Jaya Shree Textiles (JST), a unit of Grasim Industries Limited, is a part of the Domestic Textiles Business. It was incorporated in 1949 and has its only manufacturing unit at Rishra in Hooghly district, West Bengal, India. It is the first integrated Linen factory in the country with state-of-the-art facilities equipped with the latest spinning, weaving and finishing systems from Switzerland and Italy. JST has provided the evolving Indian fashion industry with an international edge with its product portfolio containing 100 per cent pure linen flax sourced from France and Belgium. JST is the pioneer in creating awareness about Linen and Linen attributes in India with the launch of “Linen Club” brand in India. The awareness created among Indian consumers helped national apparel brands to include and promote linen in their portfolio.

A leading player in the domestic linen and worsted yarn segment, the company has significantly revolutionized the Indian textile market by popularizing linen in India across a wide customer base with its brand “Linen Club”. Over the years, JST has become a preferred Textile company for Wool Tops, 100% Wool & Wool Blended Yarns- both for Weaving & Knitting, Pure Linen Yarn, Pure Linen Fabrics, Linen Blended Fabrics and pure linen and blended apparels.

Retail Stores

Linen Club is the pioneer linen brand in India with over six decades of experience. Linen Club enjoys leadership status in the Indian market and is a brand of choice for linen connoisseurs across India. Linen Club has Readyto-Wear garments and accessories under the brand “Linen Club” and “Linen Club Studio”. The linen club has an extensive range of 200 exclusive brand outlets, also a wide conglomerate of 6800 multi brand outlets for showcasing and selling finely crafted products. The entire Linen range includes extensive product line Viz. shirts, Trousers, Jackets, kurtas, T-shirts & accessories

Vikram Woollens (VW), a unit of Grasim Industries Ltd was established in 1995 and has its manufacturing unit at Malanpur in Bhind district, Madhya Pradesh, India. Vikram Woollens (VW) is the wool processing unit and a prominent player in the worsted segment of the textile industry. It has recorded robust growth in the Indian textile market across a wide customer base. VW operates exclusively in the wool segment, manufacturing worsted yarn.

Thai Acrylic Fibre Co. Ltd (TAF), an Aditya Birla Group company, is among the world’s top 5 quality acrylic fibre producers.

Incorporated in 1987, TAF produces more than 30

different types of speciality fibres including technical

fibres for high-end applications. It has a production

capacity of 120,000 MT/year. With over 30 different

varieties of acrylic fibre, we serve both the commodity

and the specialty high-end markets. The product range

comprises a variety of acrylic fibres used for making

sweaters, blankets, carpets, upholstery, soft toys and

awnings, etc. Our products enjoy worldwide recognition.

The products are sold in more than 40 countries covering

all continents. Our final products are marketed by a

number of prestigious brands in Europe and America.

Thai Acrylic Fibre plant is also one of the greenest,

cleanest and most environment-friendly acrylic fibre

plants in the world. From an installed capacity of 14,000

TPA (Tonnes Per Annum), the company has grown

consistently to reach 120,000 TPA.

Marketed under the `BirlacrilTM’ brand, the product

the range comprises a variety of acrylic fibres used

for making sweaters, jogging suits, socks, stuffed toys,

blankets, carpets and upholstery. . We also have a range

of differentiated branded products focused on various

end uses like Outdoor technical fabrics, anti-microbial

apparel, carpets & home-textiles, premium no pilling

sweaters, functional innerwear etc. We sell our fibres to

customers in over 40 countries and market our products

across the textile and apparel value chain.

Our products are synonymous with quality, consistency

and assurance. We are covering 4 entities and 4

manufacturing plants, in two countries – Indonesia

and Thailand with an annual production capacity of

170,000 MT. We have been continually upgrading our

manufacturing facilities by investing in cutting-edge

technology and best in class machines across all the

manufacturing setups. Our combined capacity is around

500,000 Equivalent ring spindles.

Aditya Birla Yarn (ABY™)

Aditya Birla Yarn (ABY™) is the brand of yarn manufactured

and marketed by OS of Aditya Birla Textiles. ABYTM yarns

consist of classical, specialty, performance, sustainable

and other iconic yarns

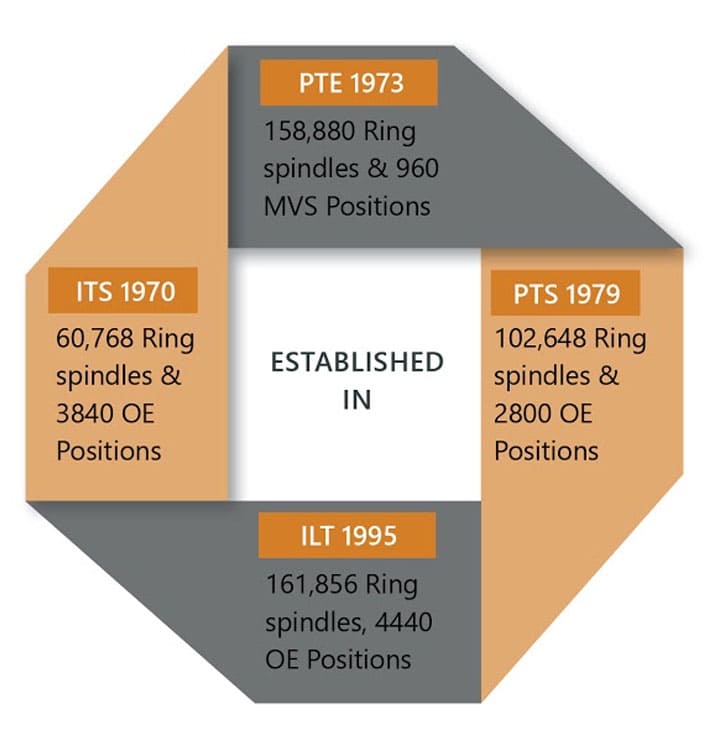

PT Sunrise Bumi is among one of ABG’s yarn manufacturing plant located in Bekasi, Indonesia. Established in the year 1979, we have increased the capacity from 17,280 spindles to 102,648 spindles and 2,800 open-end rotors. Engaged in continuous innovation and improvements across manufacturing plants for supplying best in class, quality and customized yarn, we serve the needs of our clients around the world. We are catering to ABYTM’s three major segments, namely, fashion and apparel accommodating 65-70% share of total capacity, home textiles 15-20% share of total capacity and technical textiles 10-20% share of total capacity.

PT. Elegant Textiles marked the Group’s foray into Indonesia in 1973. PTE currently having a production capacity of 158,880 spindles in addition to the latest Vortex spinning technology with 960 MVS Positions, is the world’s largest producer of rayon spun yarn, contributes to 10% of the global rayon spun yarn trade. PTE is the largest exporter of rayon and rayon-polyester spun yarn with a market share of 20-30% from Indonesia. About 70-80% of its products are exported to customers in the US, Turkey, Korea, Japan, Italy, Greece, Spain, Brazil, Argentina and other locations in Europe and the Asia Pacific region. Nearly half of PT. Elegant’s production caters to niche segments, such as high-quality fabrics for medical applications, car seat covers, upholstery and fancy yarn production among other uses.

PT Indo Liberty is among one of ABG’s yarn manufacturing plant located in Karawang, Indonesia. Established in 1995 with 21,120 Spindles, the facility is equipped with 161,856 Spindles and 4,440 Open End Rotors. We serve the needs of our clients around the world and supply the best quality of customized yarn by engaging in continuous innovation and improvement in manufacturing plant.

The first overseas venture of the Group, Indo Thai Synthetics commenced operations in 1970 with a capacity of 12,768 spindles. Today, it is Thailand’s leading synthetic yarn spinner and the largest exporter of synthetic yarn from Thailand with a 50 per cent share in the total synthetic spun yarn exports from Thailand. The current capacity has grown to 60,768 Ring Spindles and 3,840 Open End Spinning positions.

Low hairiness yarn ensures uniformity, comfort, drape & performance.

Yarn devised to offer innovative designs & trendy patterns.

Yarn offers super softness with comfort stretch & excellent recovery.

Yarn gives option of creating multiple aesthetics by playing with dyeing or finishing.

Yarn offers wool like hairy effect.

Yarn offers metallic / shiny effect in the garment.

Yarn offers deep, everlasting colour in every single fibre to have vibrant shades wear after wear & wash after wash.

Inherent flame resistant yarn which are highly durable to multiple washes.

Range of yarn for hometech segment.

Range of multifold yarns for industrial applications.

Range of products like Antimicrobial yarns for Medical application.

Range of performance yarns

| ENTITY | FY 2018-19 | FY 2019-20 |

|---|---|---|

| JST & VW |

Winner of “Outstanding Accomplishment in

Corporate Excellence” CII-ITC Sustainability Awards 2019 |

|

|

All the FY18-19 awards were won in 2019. NECA & CII ENCON mentioned twice for same award in different FYs. |

|

|

|

2nd Runners Up at “12th CII Energy

Conservation Awards 2019” Category: Large

Scale Companies CII Energy Conservation Awards 2019 |

||

| JST & VW PERFORMANCE AT CCQC & NCQC AWARDS ORGANISED BY QCFI | ||

| Year | Competition | TEAM (JST+ VW) | RESULT |

|---|---|---|---|

| FY 2018-19 | CCQC | 6 + 3 | 8 (GOLD), 1 (SILVER), 2 (BRONZE) |

| NCQC | 6 + 3 | 3 (PAR EXCELLENCE), 4 (EXCELLENCE), 1 (DISTINGUISHED) | |

| FY 2019-20 | CCQC | 5 + 3 | 7 (GOLD), 1 (Silver) |

| NCQC | 5 + 2 | 2 (PAR EXCELLENCE), 5 (EXCELLENCE) |

| TAF |

|

AMCHAM CSR Excellence Recognition’ Award: Aditya Birla Group, Thailand |

| ILT | 2nd Most Innovative Project 2018 Aditya Birla Group (Textiles Business) |

IMC RBNQA Performance Excellence Trophy 2019

cycle in the Overseas Category (3 unit) South East Asia (Indonesia) Winners REPRISM 2019 - De Risking of open End (Aditya Birla Group) |

| PTS |

|

RBNQA National Quality Award, 2019-20 |

| PTE |

2nd Best Improved Performance in

Sustainability 2018 5th Sustainability Conference of the Textile Business Aditya Birla Group, 2019 |

RBNQA National Quality Award, 2019-20 |

| ITS | Nil | Finalist in Asia’s Best Supply Chain Reporting, Asia Sustainability Reporting Awards (ASRA) |

5th Sustainability Conference of the Textile Business Aditya Birla Group, 2019

The National Energy Conservation Award (NECA) – 2019 by the Bureau of Energy Efficiency, DT

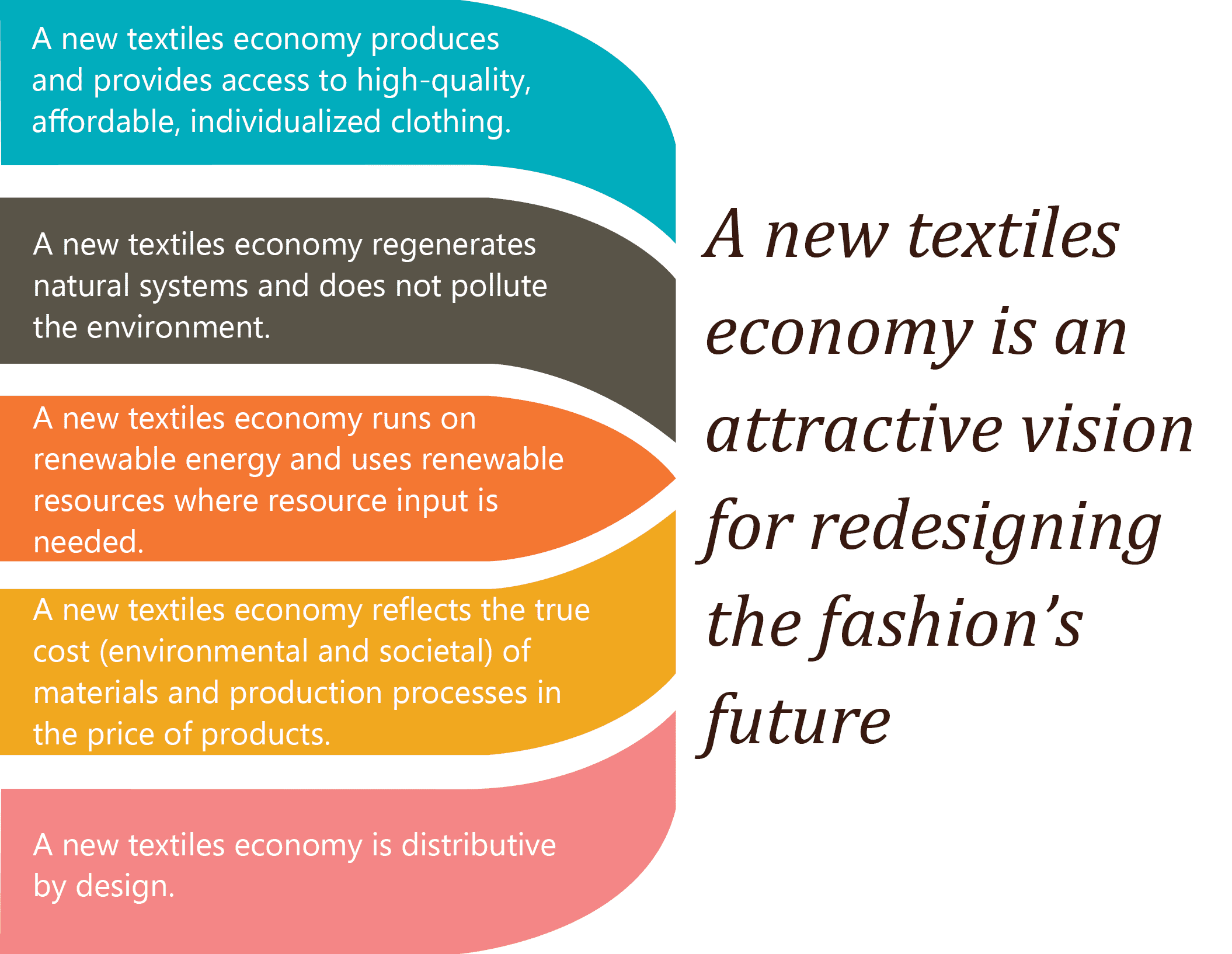

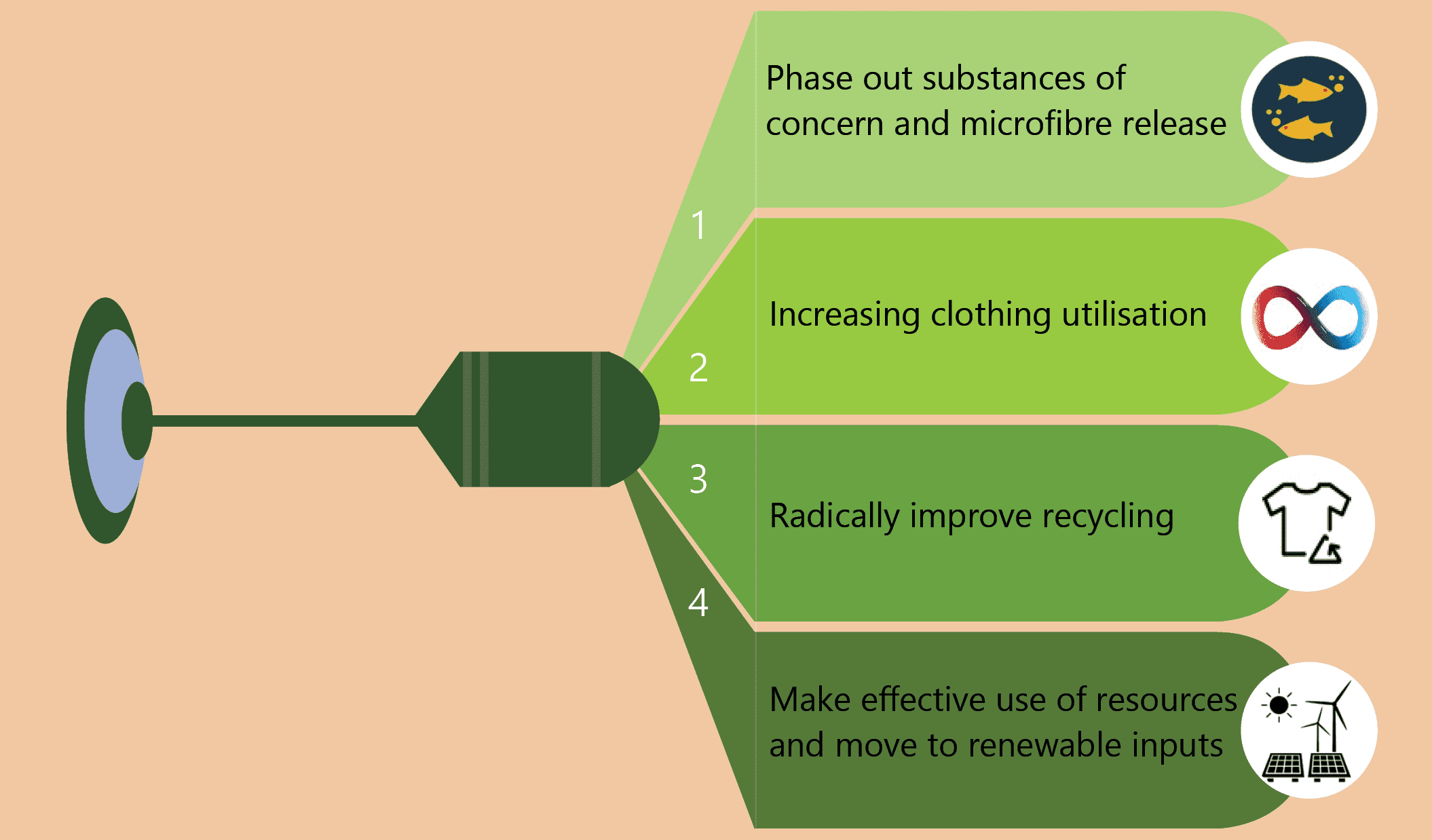

Our innovations for a new textile economy are based on the principles

of a circular economy, in which we envision fibres, fabric and clothes are

manufactured, utilized and disposed of at their highest value and minimize

the waste by closing the loops of the system. Innovations for a new textiles

economy – creating clothing that by design circulates in a system that

maintains its value.

Our continuous innovations in this direction provide us with the opportunity to

deliver substantially better economic, societal, and environmental outcomes.

Launching of various recycled fibres, value-added fibres, making use of

resources and move to renewable inputs are part of Aditya Birla Group’s

textile business’ commitment to circularity and sustainable practices.

We are also envisioning a process of developing fibres using post-consumer

clothing as inputs, for which we are actively looking for technology enabled

partners to achieve our goals.

Our innovative products based on the idea of circularity and sustainability

are appreciated by various stakeholders who provide strength to develop our

portfolio through significant Research and technology.

Our new textile economy is based on the vision of the Ellen MacArthur foundation which defines Attractive Vision of a New Textile Economics that Works.

Substance of concern

Oeko Tex R REACH SVHC

Micro-fibre

Many of our antibacterial fibre,yarn, fabric and apparel require less washing and hence generate less micro fibre

Ensuring traceability

More functions

Recycled Inside

Recycled Outside